Polyacrylamide (often abbreviated as PAM) is a synthetic polymer that has become an indispensable tool across numerous industries. Its unique chemical properties, particularly its ability to interact with water and suspended particles, make it one of the most widely used water-soluble polymers in the world.

Chemical Structure and Forms

At its core, polyacrylamide is formed by the polymerization of acrylamide monomers. Its long-chain structure contains amide groups (-CONH₂), which are highly hydrophilic (water-attracting). This allows the polymer to dissolve readily in water and perform its key functions.

PAM is rarely used in its pure, non-ionic form. It is most commonly synthesized as a copolymer, modified with ionic groups to enhance its performance for specific applications. This results in three primary types:

Cationic Polyacrylamide: Carries a positive charge. This is highly effective for interacting with negatively charged particles, such as organic sludges and clays.

Anionic Polyacrylamide: Carries a negative charge. It works well with positively charged particles, like certain metal hydroxides.

Non-ionic Polyacrylamide: Has no charge and is used where ionic interference is a concern.

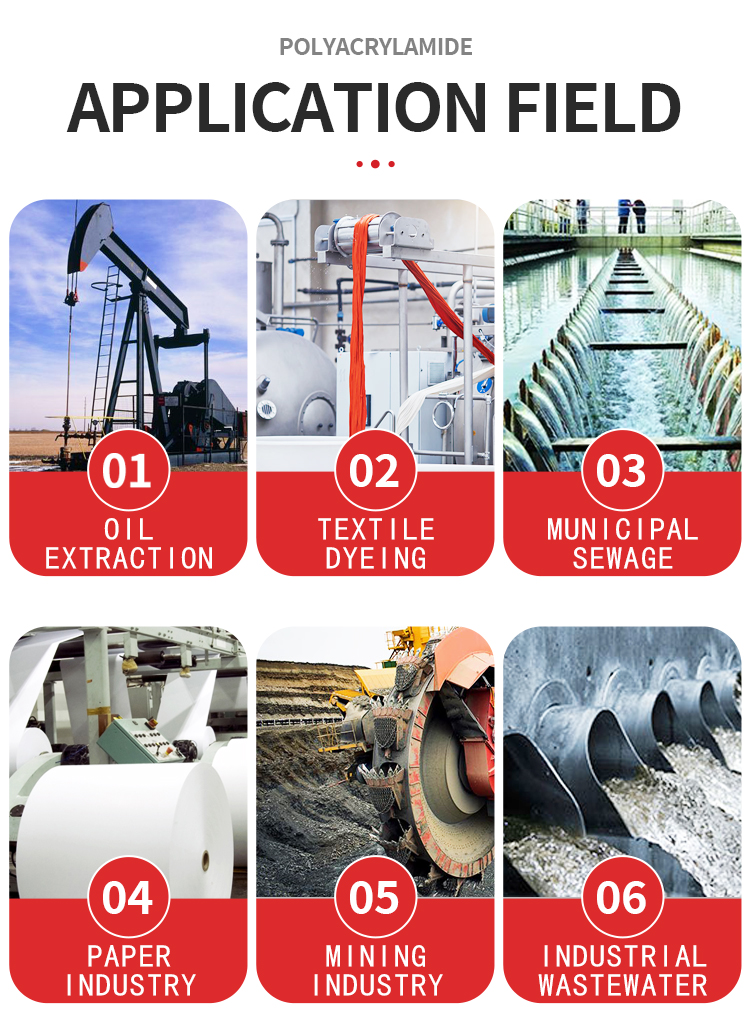

Key Applications

The utility of polyacrylamide is vast, but its most critical applications are in water management and industrial processes.

- Water and Wastewater Treatment: This is the largest application for PAM. It is used as a flocculant, meaning it causes suspended fine particles in water to clump together into larger aggregates called flocs. These flocs then settle easily or can be filtered out, resulting in clarified water. This process is vital for purifying drinking water, treating industrial wastewater, and thickening sludge in municipal sewage plants.

- The Petroleum Industry: In oil extraction, polyacrylamide solutions are injected into oil reservoirs. Their high viscosity helps to push out oil that is otherwise trapped in rock formations, a process known as Enhanced Oil Recovery (EOR). This significantly improves the amount of oil that can be extracted from a well.

- Paper and Pulp Manufacturing: PAM is used as a retention aid to bind fine particles and pigments to paper fibers, improving the efficiency of paper formation and reducing material loss in wastewater. It also serves as a strengthening agent, enhancing the dry strength of paper products.