The dosage of polyacrylamide

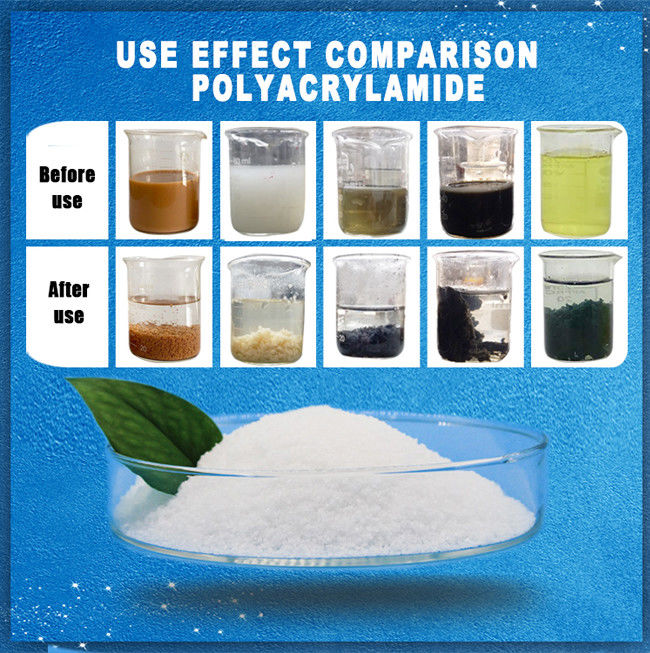

Because polyacrylamide (PAM) has the characteristics of good sewage treatment effect, small dosage, and low cost of use, many customers who need to treat sewage will use polyacrylamide, but many customers will care about the amount of polyacrylamide used in a ton of sewage? Generally speaking, it is difficult to determine the amount of polyacrylamide, because the quality of sewage and treatment equipment are different, resulting in different amounts of polyacrylamide. Below, Henan Safe will analyze the dosage of polyacrylamide in detail from three aspects.

1. Different models and molecular weights

The type of polyacrylamide determines its dosage, and the dosage of different types is also different, such as the same anionic polyacrylamide, 15 million molecular weight and 8 million molecular weight. The two models treat the same amount of sewage completely differently, possibly by a factor of two or more.

2. Different sewage and water quality concentrations

The quality and concentration of sewage in different industries are different, which determines the type and amount of polyacrylamide. If it is the same coal washing plant, the pH value of the coal washing wastewater and the content of various additives and heavy metals are different, so the amount of polyacrylamide is also different. The wastewater quality of printing and dyeing plants, paper mills, and slaughterhouses is much more complicated than that of coal-washing plants. Small changes can change the dosage.

3. Different use environments and equipment

The use environment of sewage treatment of different manufacturers is different. Different dissolution ratios, dissolution time, flocculation time and the influence of process equipment will change the amount of polyacrylamide. If the dissolved ratio is too high, it will make it more difficult for flocculation to control the dosage. If the dissolution time is too short, it will lead to poor product effect, increased usage and waste. For different treatment processes and equipment, the amount used is also different. For example, a plate and frame filter press saves more than a belt filter press.