The livestock and poultry breeding industry is an important part of agriculture and rural economy, and the vigorous development of the livestock and poultry breeding industry has caused increasingly serious environmental pollution. At present, large-scale livestock and poultry farms all over the country discharge a large amount of high-concentration livestock and poultry wastewater every day. Wastewater contains pollutants such as CODcr, ammonia nitrogen, heavy metals, residual veterinary drugs and various pathogens. If it is discharged directly without treatment, it will form serious pollution. The main hazards are as follows:

1. Damage to water bodies. Aquaculture wastewater has typical “three highs” characteristics, namely high CODcr, high ammonia nitrogen and high SS.

2. Damage to the atmospheric environment. Under anaerobic conditions, livestock and poultry wastewater will produce a large amount of NH3, H2S and other malodorous gases, which will affect and damage the health of livestock, poultry and surrounding residents.

3. Damage to farmland and crops. Aquaculture wastewater contains a large amount of nutrients such as nitrogen, phosphorus, and potassium. If it is directly, continuously, or excessively applied without any treatment, it will have adverse effects on soil and crop growth.

No matter what comprehensive measures are taken to treat aquaculture wastewater, solid-liquid separation must be carried out first.

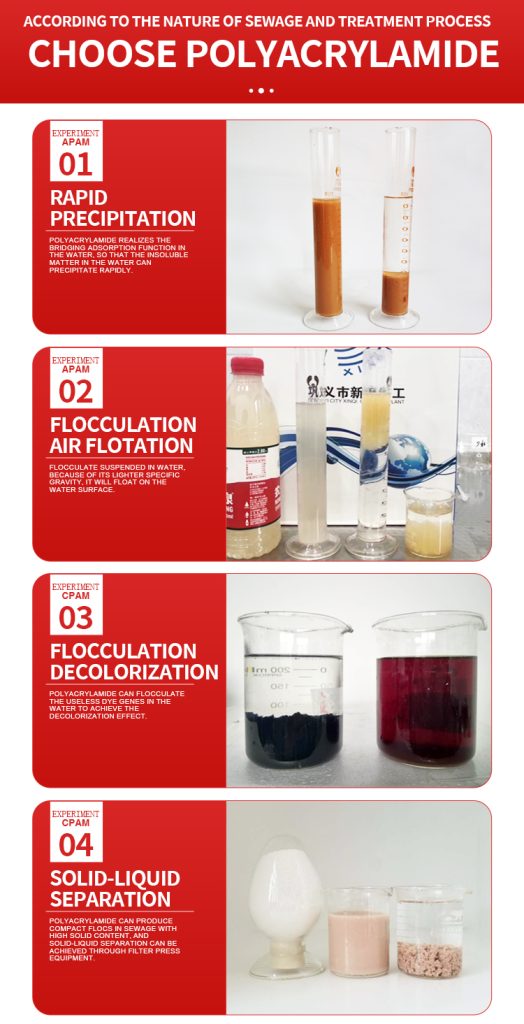

At present, the treatment of aquaculture wastewater mainly includes biochemical treatment, adding flocculant for precipitation, pressure filtration and mud pressing, and clear water discharge. To purify sewage, three basic conditions must be met: sedimentation velocity, residence time, and sludge discharge. If the water flow is too fast and the sedimentation time is not enough, it is difficult for the sewage to sink and clarify. Only in the first two cases can the sewage become clear, but the settled sludge floats anaerobically for a long time, and the settled water turns black and dirty. In order to speed up the purification of sewage, flocculants or coagulants such as polyaluminum chloride and polyacrylamide can also be added according to different sewage water quality.

Water sample detection:

The sewage sample is aquaculture sewage, and the pH value is 6.5-8 which is neutral. The content of organic matter in the water quality is high and the content of heavy metals is low. Sewage samples have high chroma and less suspended solids.

Test 1: Add 10ml polyaluminum chloride to 300ml sewage to produce smaller flocs. Then add 4ml of anionic polyacrylamide and stir evenly. The flocs do not change much, and the sedimentation effect is good. The color of the water quality changed slightly.

Suggestion: Anionic polyacrylamide has a general flocculation and decolorization effect and is not recommended for use.

Test 2: Add 10ml of polyaluminum chloride to 300ml of sewage to produce small flocs, then add 4ml of cationic polyacrylamide and stir evenly. The flocs change greatly, the particles are larger, and the agglomeration is better. The sedimentation speed is fast, and the water color is reduced by nearly 60%-75%. The odor has been reduced by nearly 80%, and the clear water liquid in the upper layer has been greatly improved, but the appearance is visually slightly yellowish. The COD of the supernatant aqueous solution is 60 mg/L-110 mg/L, reaching the national sewage discharge standard.