1. traits

Polyacrylamide (PAM), also known as flocculant No. 3, is a water-soluble linear polymer polymerized by free radicals from acrylamide (AM) monomers. It has good flocculation and can reduce the inter-liquid Friction resistance can be divided into four types: non-ionic, anionic, cationic and amphoteric according to ionic characteristics. Polyacrylamide is white powder or small particles with a density of 1.32 g/cm3 (23°C), a glass transition temperature of 188°C, and a softening temperature close to 210°C. Completely dry polyacrylamide is a brittle white solid; commercial polyacrylamide is usually dried under moderate conditions, generally with a water content of 5% to 15%, and the polymer film prepared on a glass plate is transparent, hard and easy to dry. broken solids. Polyacrylamide can be dissolved in water in any proportion, and the aqueous solution is uniform and transparent. The viscosity of the aqueous solution increases significantly with the increase of the relative molecular weight of the polymer. PAM is insoluble in most organic solvents such as methanol, ethanol, acetone, ether, aliphatic and aromatic hydrocarbons.

2. Mechanism of action

cThere are a certain number of polar groups in the PAM molecular chain, which can absorb the suspended solid particles in the sewage, bridge the particles or through the neutralization of the charge, so that the particles can aggregate to form large flocs, therefore, it can accelerate the suspended solids The sedimentation of medium particles has very obvious effects of accelerating solution clarification and promoting filtration.

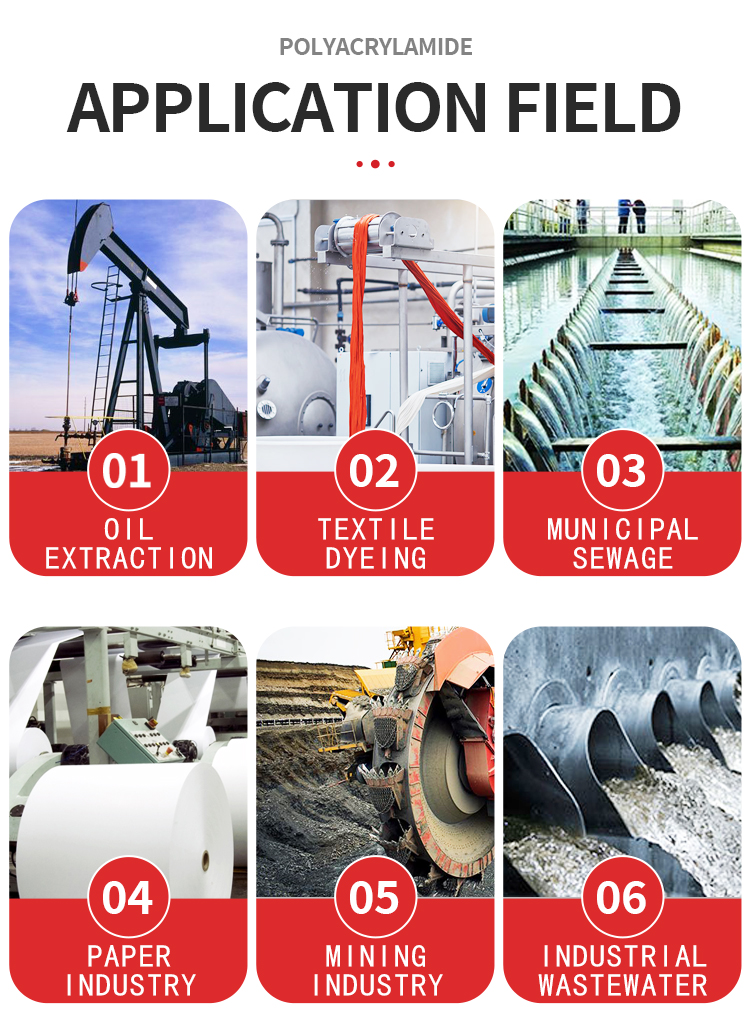

3. Purpose

The main application fields of polyacrylamide in my country are petroleum exploration, water treatment, papermaking, superabsorbent resin, metallurgy and coal washing, etc. In water treatment, the amide group of polyacrylamide can be affinity and adsorbed with many substances to form hydrogen bonds. High molecular weight polyacrylamide forms a “bridge” between the adsorbed particles to form flocs, which is conducive to the sinking of particles. Polyacrylamide flocculant can adapt to various flocculation phenomena, its dosage is small, its efficiency is high, it generates less sludge, and it is easy to post-treatment, so it has special value for some situations. my country’s raw water treatment, urban sewage treatment and industrial wastewater treatment industries all use polyacrylamide as a water treatment chemical to varying degrees. Polyacrylamide is currently the most widely used and most efficient polymer organic synthetic flocculant.

4. How to use

Granular polyacrylamide flocculants cannot be directly added to sewage, and must be dissolved in clean water at room temperature (such as tap water) before use. When the water temperature is lower than 5°C, the dissolution is very slow, and the dissolution rate is accelerated when the water temperature rises, but above 40°C will accelerate the degradation of the polymer and affect the use effect. The concentration of the prepared polymer solution is recommended to be 0.1%~0.3%, that is, add 1~3g polymer powder to 1L water. When dissolving, it should be noted that the flow rate should not be too fast (especially the automatic dosing device), so as to prevent polyacrylamide from agglomerating and causing “fish eyes” phenomenon, and even block the pipeline; the stirring speed is generally 200 r/min, and the time is not Less than 1 hour; Properly increasing the water temperature by 20-30°C can speed up the dissolution, and the maximum temperature of the liquid should be less than 60°C.

5. Precautions

Commercial polyacrylamide contains toxic unpolymerized acrylamide monomer, so my country stipulates that its maximum allowable amount is 0.01 mg/L in drinking water treatment. In order to prevent the degradation of polyacrylamide, the storage temperature of its aqueous solution should be controlled not higher than 40°C. In order to prevent exposure, a small amount of stabilizers can be added to the solution, such as sodium thiocyanate, thiourea, sodium nitrite and non-solvent methanol.