There are two main types of flocculants used in the treatment of coal mine wastewater: inorganic flocculants and organic flocculants. In coal mine coal washing and wastewater treatment, polyacrylamide (PAM) is one of the most common types of organic flocculants. The following is a specific classification and its application in coal mine wastewater treatment:

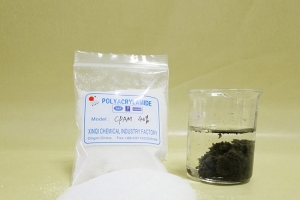

1. Organic flocculant-polyacrylamide (PAM)

a. Anionic polyacrylamide: Suitable for treating alkaline coal washing wastewater, promoting the coagulation and precipitation of suspended particles through charge neutralization and adsorption bridging.

b. Cationic polyacrylamide: Suitable for treating acidic coal washing wastewater, also through charge neutralization and adsorption bridging, but more commonly used in sludge dewatering process to promote solid-liquid separation and improve dehydration efficiency.

c. Non-ionic polyacrylamide: Used under certain specific conditions, suitable for sewage treatment with low suspended matter concentration.

2. Inorganic flocculant-poly aluminum chloride (PAC): It is a highly efficient inorganic polymer coagulant, suitable for various water quality conditions, and can effectively remove suspended matter, organic matter, chromaticity and some heavy metal ions in water.

In practical applications, it is usually necessary to select the most suitable type of flocculant according to the specific characteristics of sewage (such as pH value, type of suspended matter, hardness, etc.), and determine the optimal dosage and treatment conditions through experiments. Sometimes, in order to achieve better treatment effects, a combination of two or more flocculants is used. For example, an inorganic flocculant is used for preliminary treatment, and then an organic flocculant is used for deep treatment to achieve a higher suspended matter removal rate and water purification effect.